Utilizing self-regulating technology, these heating cables are designed to meet the full spectrum of heating needs in Cold and Freezer rooms. Their self-regulating construction ensures protection against burnout, especially at ‘cross-over’ points, as the cable automatically adjusts its heat output along its entire length based on the surrounding temperature.

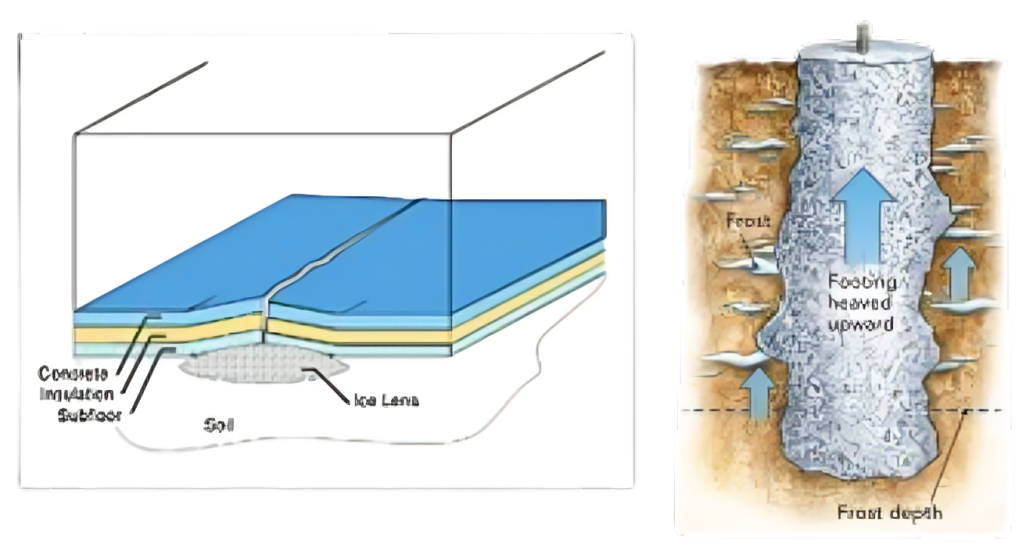

Frost heave happens when the ground beneath a cold storage facility freezes and expands, leading to cracks, slopes, and uneven flooring. As the cold room’s low temperature transfers into the ground, natural moisture freezes, expands, and pushes up the floor, causing structural damage and unsafe conditions.

To prevent this, cold storage floors are built with multiple layers of concrete and insulation. However, without a floor heating system, soil temperatures can fall below freezing, forming ice lenses that cause buckling. A properly designed heating system applies just enough energy to keep the ground above freezing without affecting the cold room temperature, with insulation directing the heat effectively.

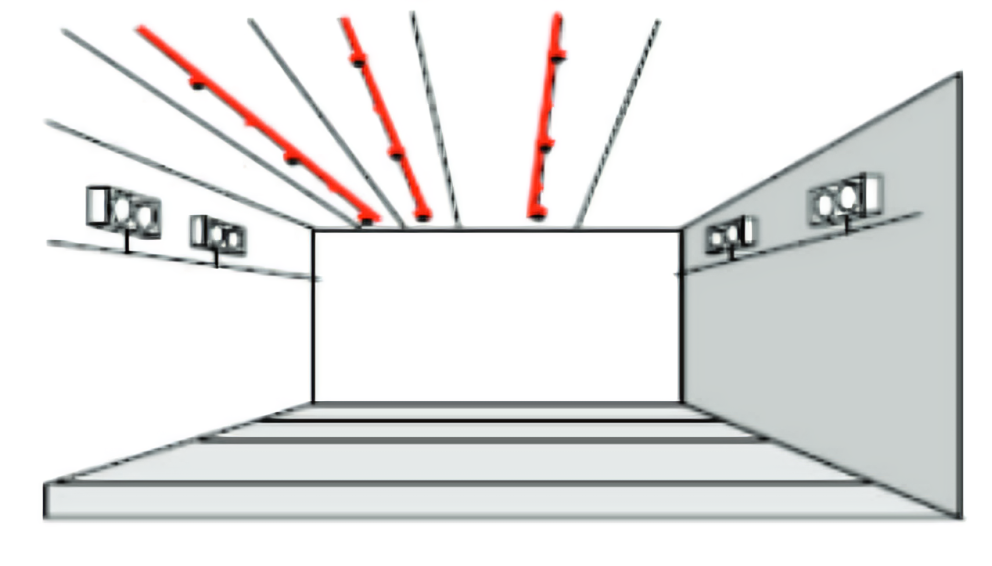

The heating system is based on IEEE 515.1-1995 standards. Design inputs like cold room size, insulation details, and concrete thickness are needed. The system maintains the substrate at 5°C to prevent frost heave. It uses self-regulating heating cables with copper bus wires, a self-limiting matrix, thermoplastic insulation, and a tinned copper braid, operating between 220–277V AC, and suitable for installation in temperatures as low as -40°C.

Installation involves pre-fitted heating mats placed on the subfloor as per the design, with weatherproof junction boxes, digital controllers, ELMCB/RCBOs, and RTD sensors ensuring precise operation and safety.

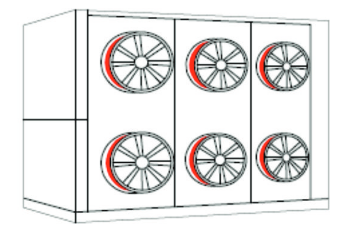

We provide heating solutions for walls and stands, with the control system installed at a nearby convenient location. In Installation Method 2, the heating cable is placed inside a minimum 3/4″ conduit, embedded approximately 50mm below the insulation layer within the base substrate. Junction boxes are installed along the wall or in other suitable areas as per the design, ensuring they are easily accessible for wiring and maintenance without removing any concrete or building parts. Each junction box must be positioned at least 50mm above the finished floor level.

Conduits should be spaced 1.2 meters apart, measured center to center. Heating cables must be tested using a megger at a minimum of 1,000 VDC. Testing must be conducted at least three times, with a minimum acceptable insulation resistance of 20 megohms, regardless of circuit length.

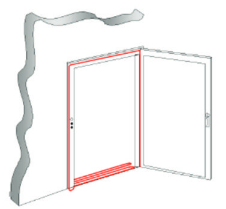

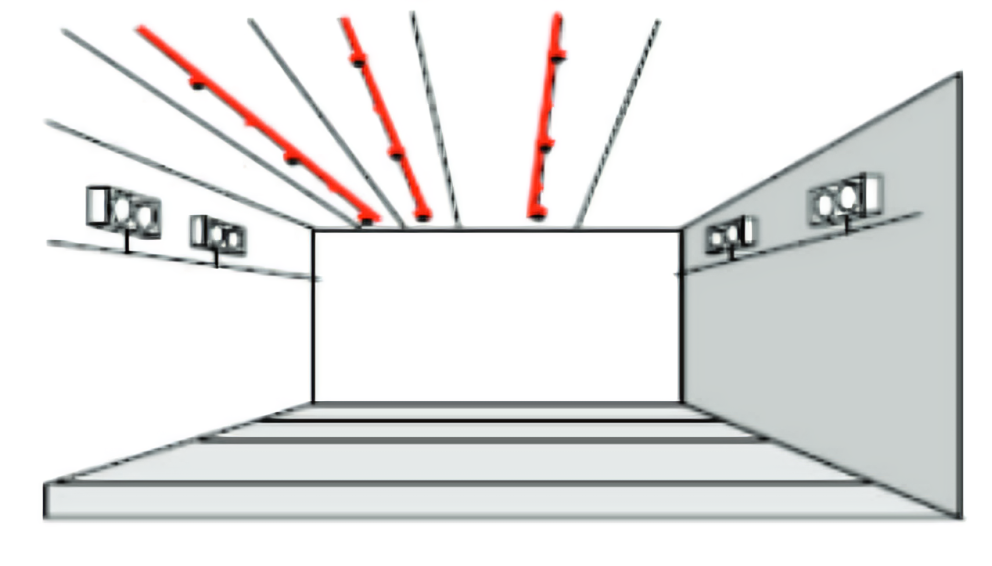

The heating cable increase the temperature of the door frame surface above 0 deg C and prevents ice formation between door and frame. The ensures the safety and door is always in openable condition

The heating cable increase the temperature of the door frame surface above 0 deg C and prevents ice formation between door and frame. The ensures the safety and door is always in openable condition

The heating cable increase the temperature of the door frame surface above 0 deg C and prevents ice formation between door and frame. The ensures the safety and door is always in openable condition

The heating cable increase the temperature of the door frame surface above 0 deg C and prevents ice formation between door and frame. The ensures the safety and door is always in openable condition

The heating cable increase the temperature of the door frame surface above 0 deg C and prevents ice formation between door and frame. The ensures the safety and door is always in openable condition

The heating cable increase the temperature of the door frame surface above 0 deg C and prevents ice formation between door and frame. The ensures the safety and door is always in openable condition

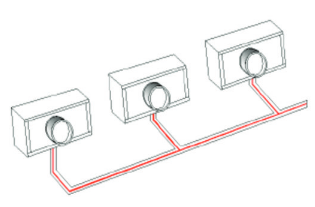

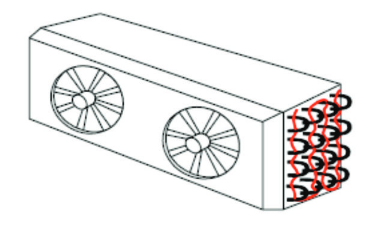

During the defrost cycle, water droplets from the evaporator coils collect in the drip tray. Without proper heating, ice can form in the tray, leading to blockages and operational issues. This can be effectively prevented by installing a heating cable. We also offer complete heated drip trays as a ready-to-use solution.